News & Views

Hatchery Products and Services

Research

Technology

Japan university develops software for automated sorting

October 11, 2019 By Ruby Gonzalez

Staff at Kindai University’s Aquaculture Research Institute sorts out fingerlings.

Staff at Kindai University’s Aquaculture Research Institute sorts out fingerlings. A software for mechanizing a portion of fingerling sorting has been developed in Japan, freeing up skilled workers from crucial but very time-consuming task.

The project is a collaboration between Kindai University’s Aquaculture Research Institute and partner company, Toyota Tsusho. The latter brought in Microsoft Japan to assist in the automation process.

A control system automatically regulates the flow of water through pumps that transfer fingerlings from their pens to conveyor belts for sorting. Continuous monitoring and flow adjustments are done using Internet of Things (IoT) and artificial intelligence (AI) tools.

“The next step is [understanding] how AI stores the fish selection criteria,” Ryota Sakishita of the Aquaculture Technology and Production Center at Kindai University told Hatchery International. He said the completion date for this phase has not been determined.

The ultimate goal is the mechanization of the fingerling inspection work using software that recognizes defective products using AI and image recognition, among other things.

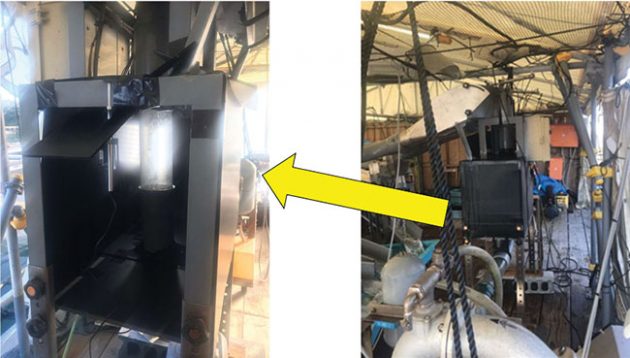

Photo on the left shows the black box interior. A camera detects fish flowing into the pipe.

“We believe we need both hardware that sorts without actually damaging the identified fish. In order to achieve this, a large amount of information and technology for judging from 360-degree image information of moving fish are required, so various methods are being verified,” he said.

The mechanization, which started in February, has eased the workload of staff at the university’s Aquaculture Research Institute, who used to hand-sort as many as 250,000 seabream fingerlings a day. The annual production is about 12 million fingerlings, which are sold to fish farms that grow them to adult size for the market.

The sorting system begins with gathering fingerlings near the mouth of the pump. Before the automation of the pump control system, there was a full-time staff who adjusted the pump’s water flow to the conveyor belt. This staff has since been assigned to another responsibility.

Print this page

Advertisement

- Florida’s Seaventure hatchery takes on sustainable clam production

- Whole Oceans appoints new hatchery manager for Maine operations